2023 年伊斯内尔教育之夜

Users have provided detailed feedback about the everyday running of their machines and systems and have highlighted areas which required improvement. motan-colortronic has taken these suggestions on board and has implemented them, as well as some of their own additional ideas, into the material loaders of the popular METRO G series.

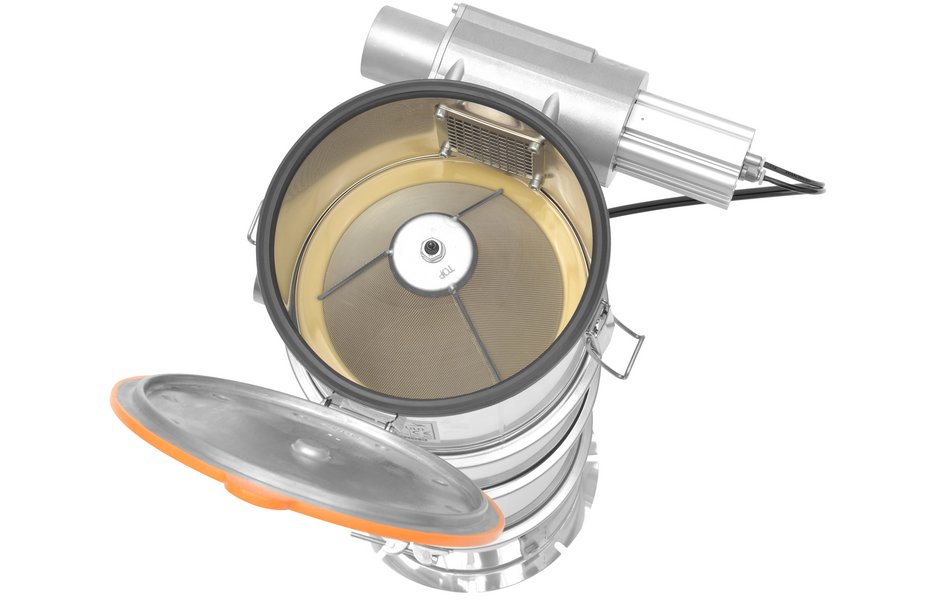

Particularly the manually operated parts were viewed critically by users. Therefore, the lid along with the hinge and latch have been reworked and redesigned to optimise handling. The shape of the lid seal was adjusted.

By reworking the implosion valve provides the METRO G material loader with even more flexibility: The pneumatic cylinder size DN32 enables operation with greater vacuum than before. Freely selectable vacuum connections between DN28 and DN60 make connection to customer's system easier. The implosion valve can be installed easily without the need for an adaptor and is available with different seal versions: The standard silicon-free seals can quickly and simply be swapped for silicon seals, for example for medical applications or for operation at high temperatures.

Another convenient feature are the new solenoid valves, which can now be operated at the touch of a button.

motan-colortronic uses customers' experiences and feedback to implement innovation in every detail and to provide greater customer benefits.